Printing Block |

As early as 3000 B.C. the Mesopotamians used stamps to impress designs onto wet clay. Before printing began, each copy of the book is written out laboriously by hand. The first people to print books were the Chinese and Japanese in the 6th century. Wooden, clay, or ivory blocks were used on which characters and pictures were engraved. The characters were printed by the raised areas of the engraving when a paper sheet is pressed against the inked block. This is known as letter pressing printing. |

A Chinese printer named Pi Sheng invented movable type around 1045; he fashioned his characters of heart-fired clay. Later

printers improved on his designs by using characters made from lead. However, movable type printing was not popular in China

as Chinese language has some 80,000 characters; their printers ultimately found it more convenient to use carved blocks.

|

German printer Johannes Gutenberg, who built his first printing press around 1440-1450 was said to be the first inventor of

a lasting system of movable-type printing. He invented the type casting - a method of making large amounts of accurate movable

type cheaply and quickly. After Gutenberg's work, printing with movable type spread quickly across Europe.

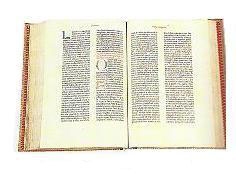

Many people thought that Gutenberg was in league with the devil because he managed to mass-produce beautiful copies of the Bible in so short a time. The font face was the best so far, and because he could move the letter blocks around, he didn't have to spend time carving out page after page, hence allowing him to spend more time on beautifying his product. |  Gutenberg's Bible |

In 1811, German inventor Friedrich Konig, discovered a way to harness steam power to a press in which a revolving cylinder replaced the flat; his machine could print over a thousand pages per hour, as compared to Gutenberg's measly 300 per day. In 1846, Richard M. Hoe invented a press that also used a cylinder to carry the type. An 1857 version of Hoe's rotary press could print 20,000 individual sheets hour, and rolls of paper replaced single sheets, further speeding the process.